Robotic Fabrication:

Compression Only Furnicular Bench

Architectural Robotics & Advanced Structural Design Final Project

with Professor Joshua Bard & Juney Lee

Collaboration with Hazel Froling, Darin Kim, and Eric Yu

Completed Dec 2024

Material Pre-Processing

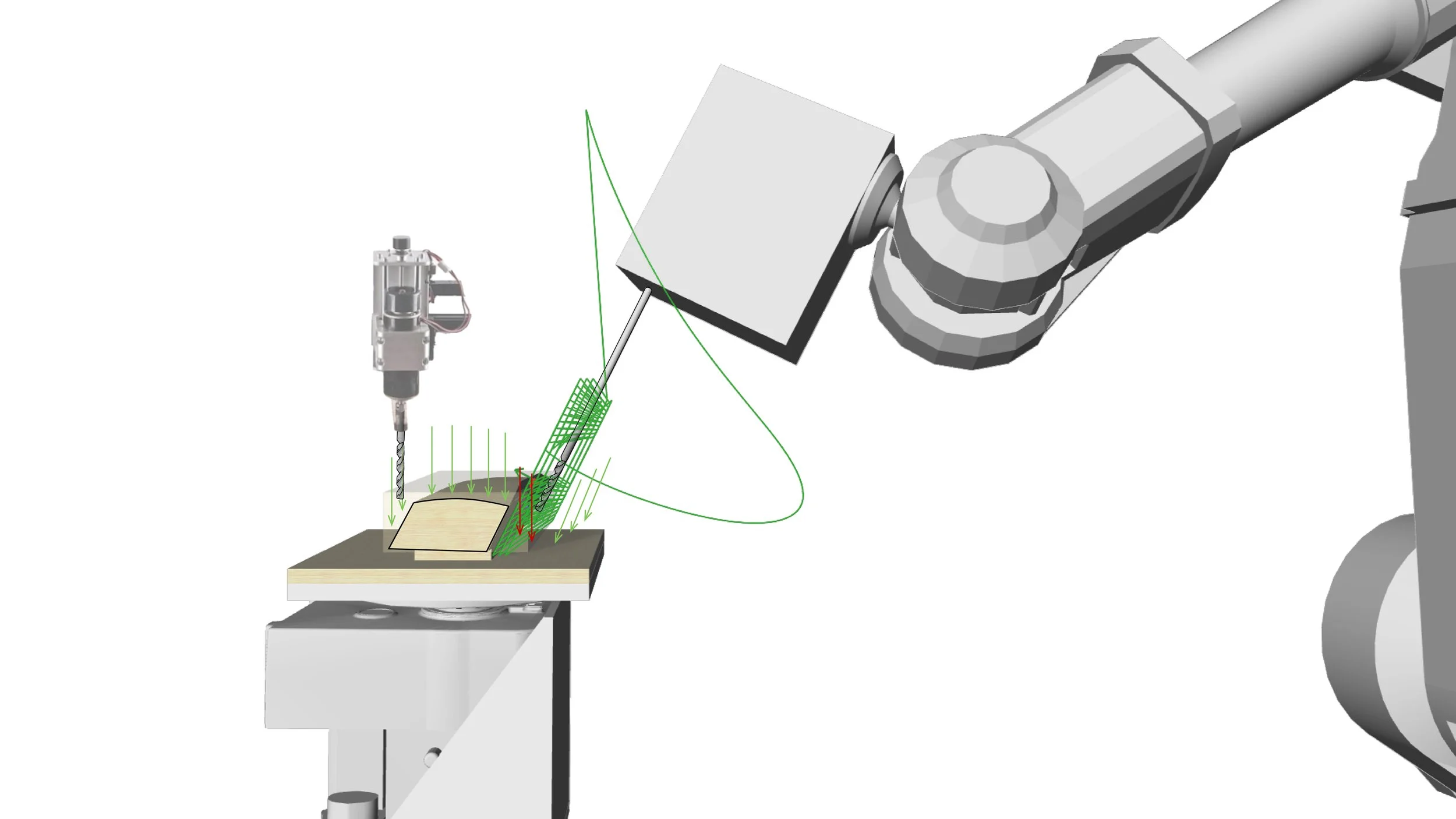

Robotic Path Planning & Cutting

Overview

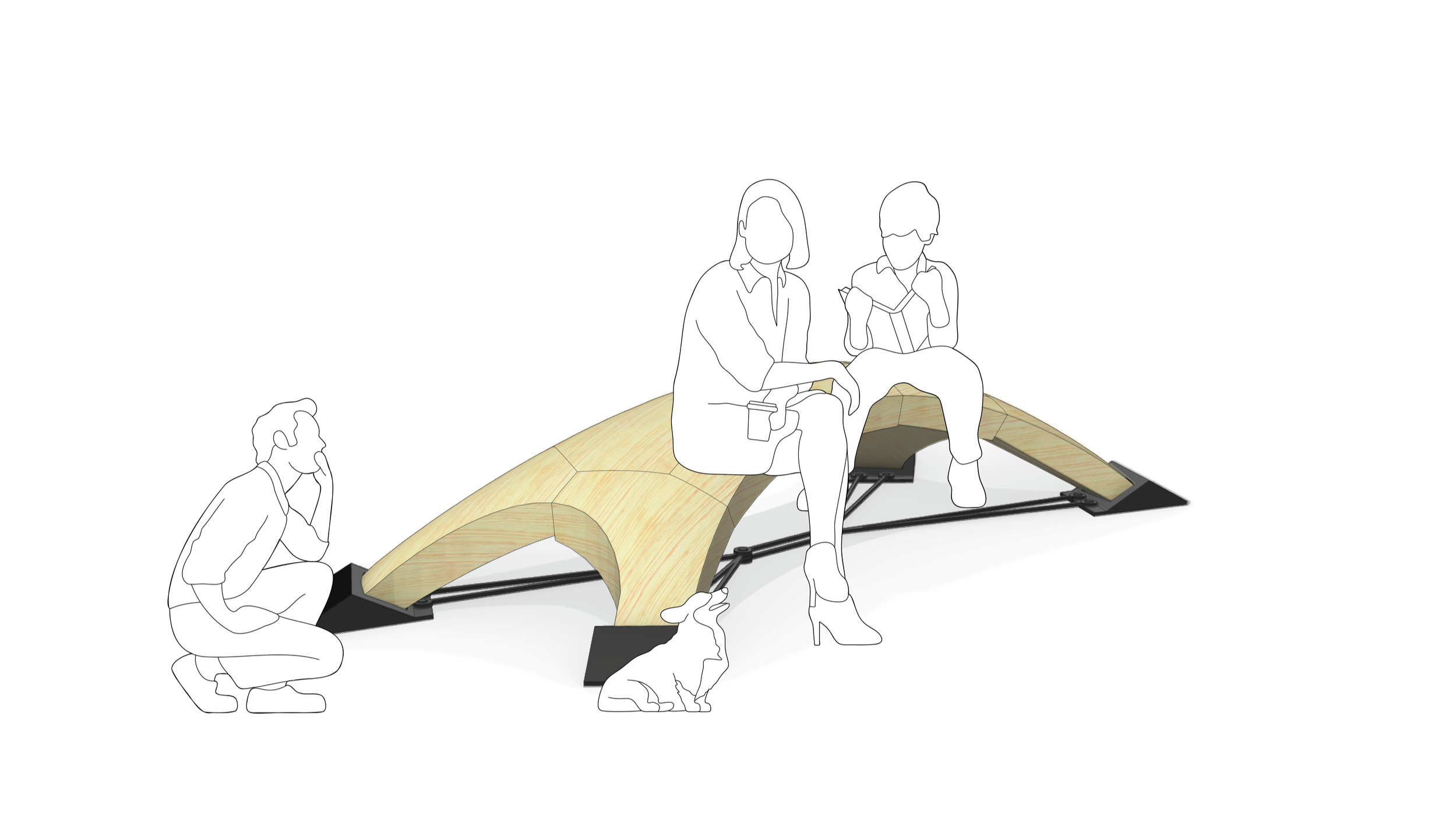

This project engineered a compression-only, dry-fit wooden bench through a high-precision robotic fabrication workflow that eliminates the need for adhesives or mechanical fasteners. By integrating RhinoVault structural optimization with custom robotic kinematics and path planning algorithms developed in Grasshopper, I translated complex 3D mesh data into precise motion control for an ABB 4400 industrial arm. The resulting system showcases a seamless digital-to-physical bridge, optimizing material efficiency and structural integrity through advanced automation and exacting geometric constraints.

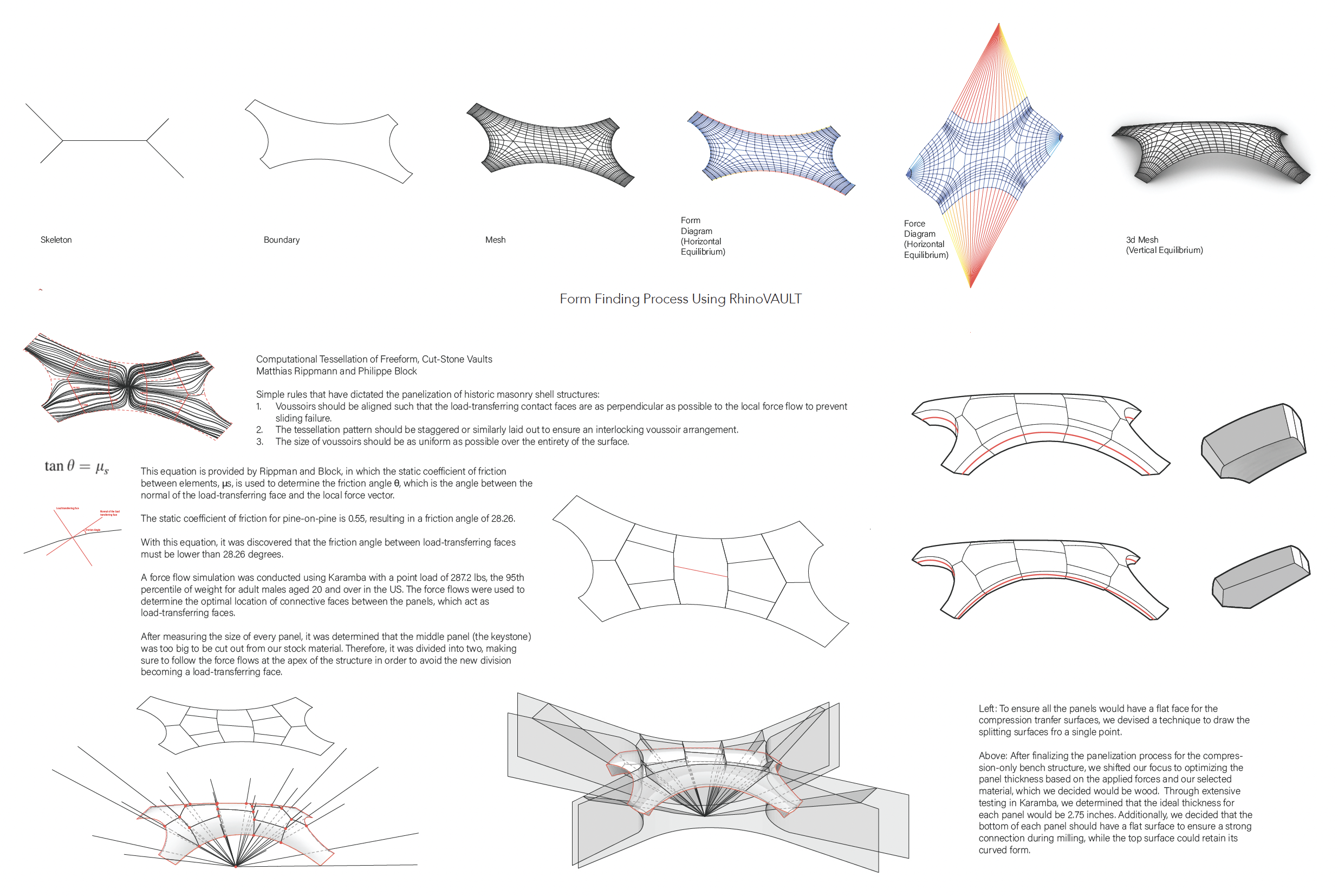

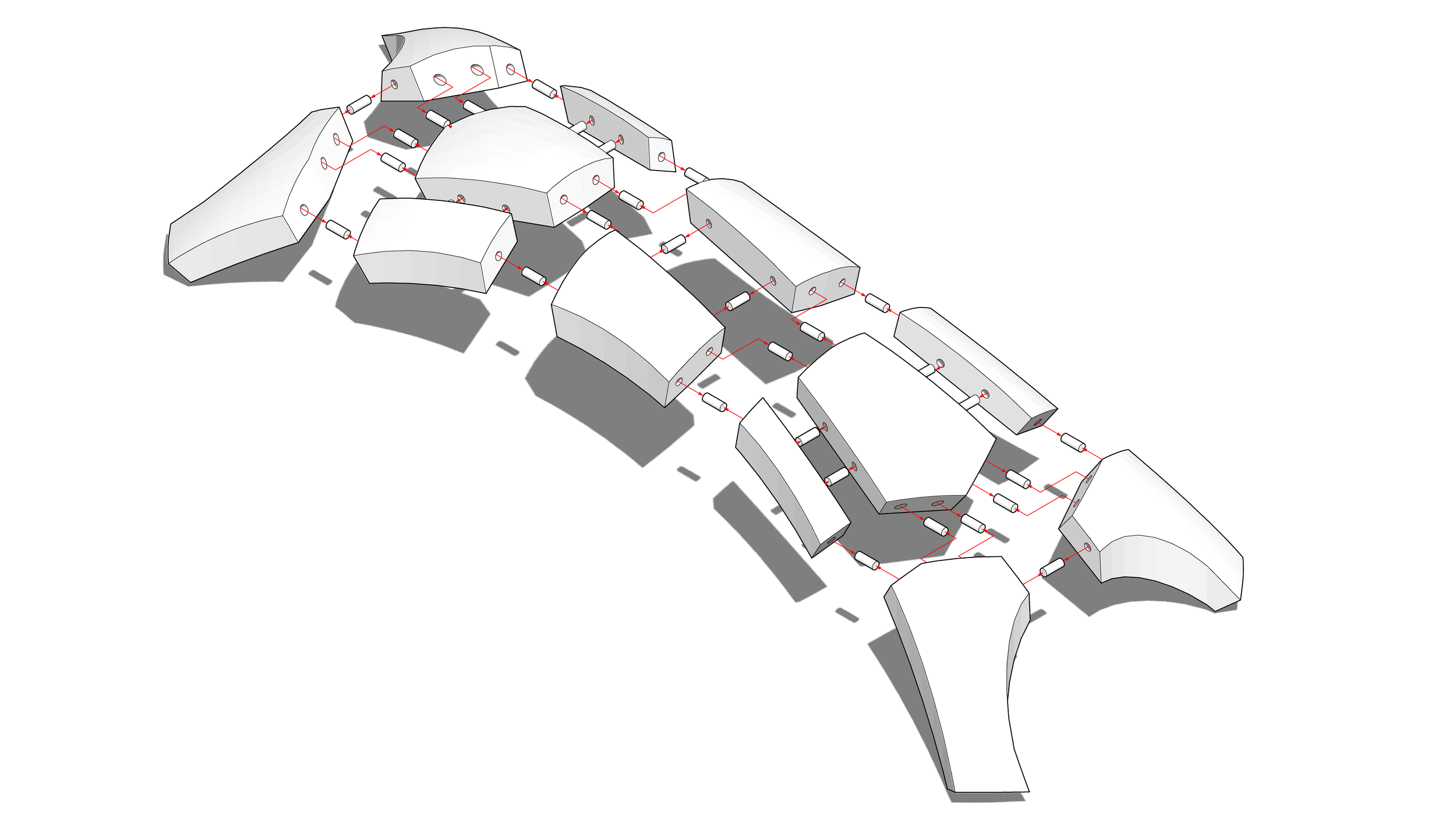

Structural Synthesis Geometric Logic

This project explores the use of architectural robotics to mill a wooden bench structure designed to be assembled using a compression-only, dry-fit technique. Leveraging RhinoVault’s structural optimization capabilities, we aim to create a stable, durable bench that relies solely on the compression of its parts for structural integrity, eliminating the need for adhesives or fasteners.

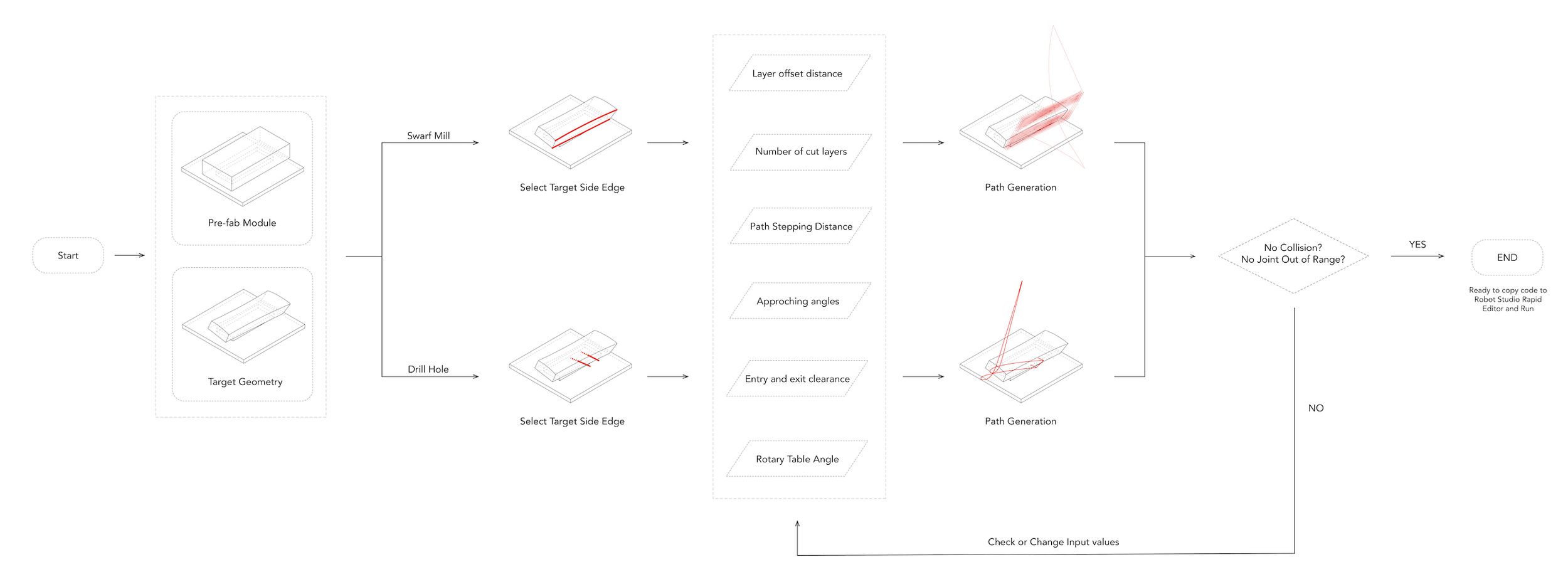

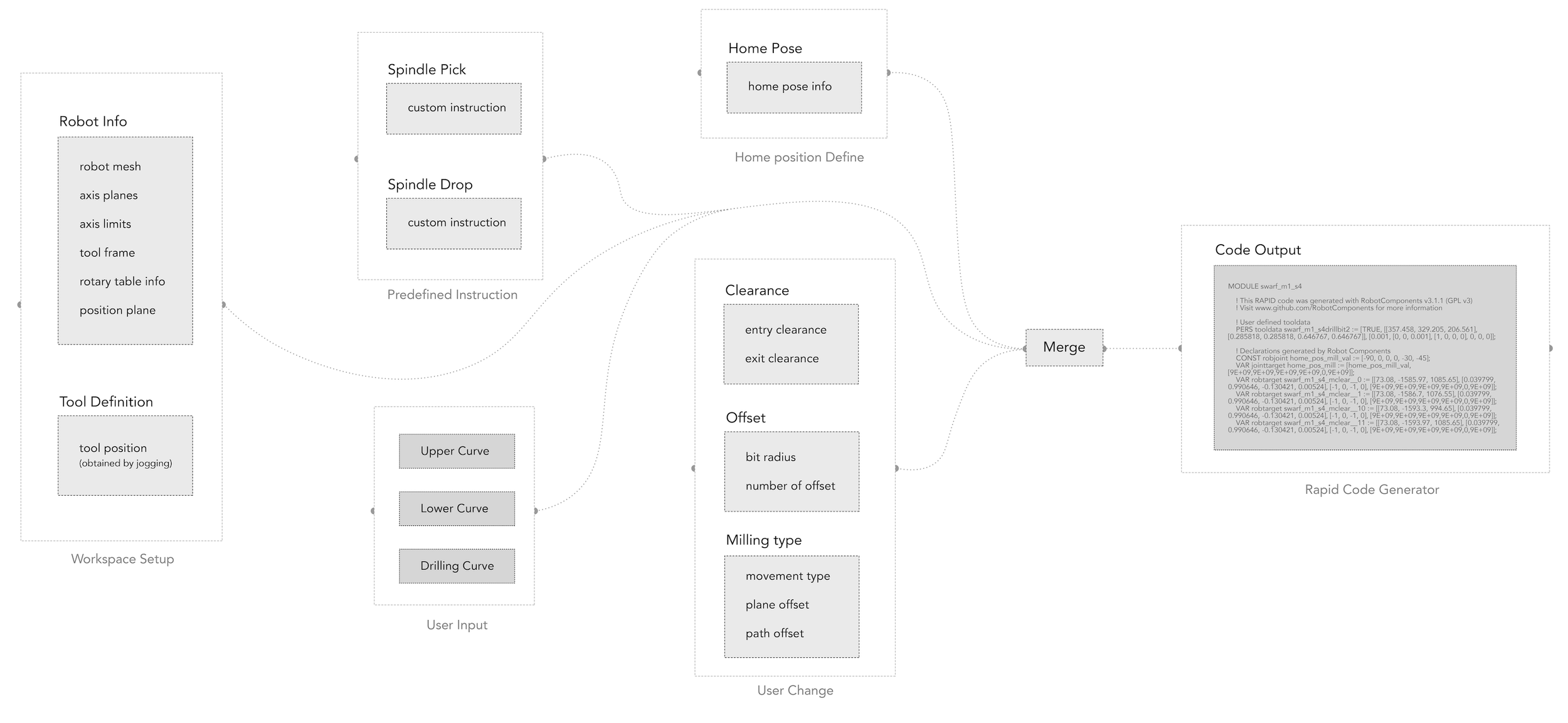

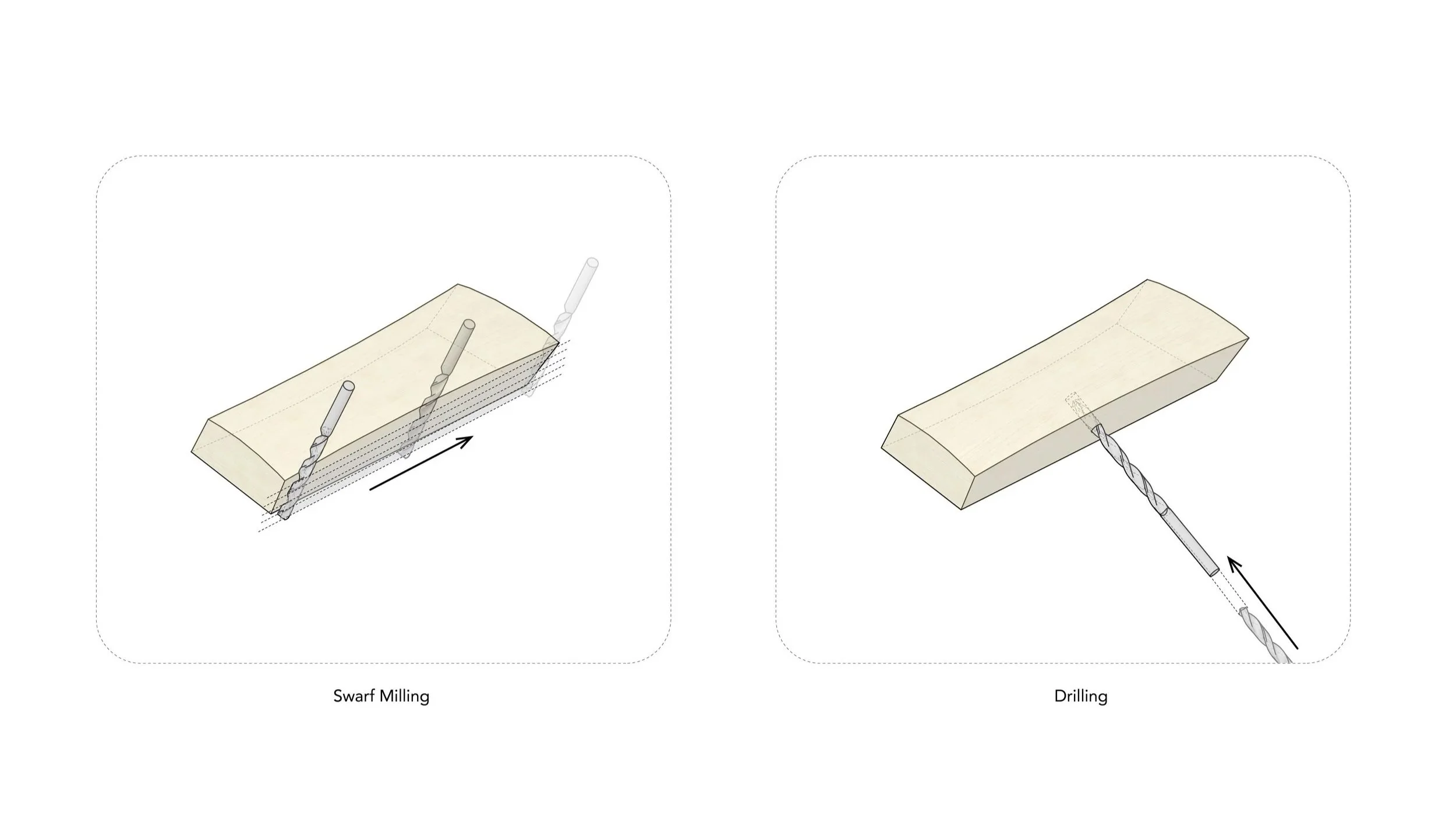

Computational Path Planning

A key focus of the project is developing custom toolpaths in Grasshopper, tailored to the specific geometries of each component in the bench. By creating precise toolpaths, we aim to ensure each part is milled accurately to meet the project’s exacting structural requirements. This workflow will allow us to produce unique, complex shapes that fit together seamlessly, supporting the bench’s dry-fit design.

Digital-to-Physical Workflow

Through this project, we seek to build practical skills in creating advanced toolpaths, which are highly relevant to the evolving field of robotic architectural fabrication. The ability to customize and optimize toolpaths for unique, structurally demanding designs is increasingly important in architecture and construction, as the industry embraces automation and precision manufacturing. This project not only results in a functional, aesthetically pleasing bench but also enhances our understanding of robotic milling techniques and digital-to-physical workflows, contributing to our broader skillset in advanced fabrication technologies.